Distillery pumps: Innovation and quality for alcohol production

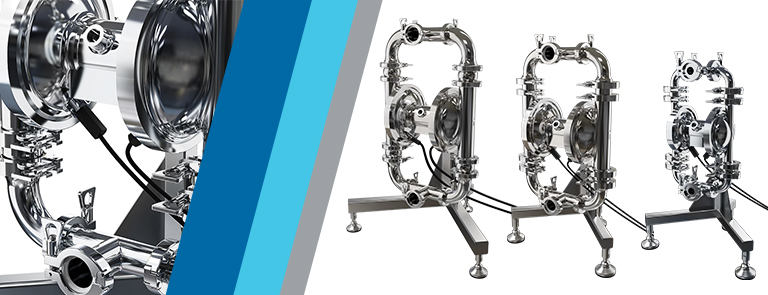

The distillery industry requires highly reliable and high-performance technologies to guarantee the quality of the final product. The most important production steps include the handling of raw materials, the handling of different ingredients and the transfer of the final distillate. These steps must be managed with precision, efficiency and safety and using appropriate technologies. Distillery pumps, in particular air-operated double diaphragm (AODD) pumps, are one of the most versatile and high-performance solutions to meet these needs. Debem’s AODD sanitary pumps are specifically designed for the beverage industry and provide superior performance at every stage of the process.

Requirements for alcohol transfer pumps

The production of distilled spirits and alcohols has a number of specific requirements that must be met in order not to compromise the integrity and quality of all the ingredients involved in the operational processes. Among the most important requirements are:

- Gentle transfer: Distillates are products that are often sensitive to flow variations and rough handling. Too aggressive handling could compromise the taste and quality of the product.

- Food compatibility: Pumps used in the spirits industry must comply with strict hygiene standards, such as FDA certification, to ensure that no contaminating material comes into contact with the product.

- Resistance to alcohol: Distillates with a high alcohol content require materials that are resistant to corrosion and wear and tear and can maintain their performance over time.

- Operational safety: handling alcohol involves risks of flammable vapours; therefore, pumps must be designed to operate safely in potentially explosive environments.

Advantages of AODD technology in distillery pumps

AODD pumps for the distillery sector are ideal for meeting these requirements, thanks to their flexibility and ability to handle different types of fluids without damaging their structure or quality. Their ability to run dry, self-priming and handle variable pressures without the need for complex controls makes them an excellent choice for distilleries. In addition, they are easily portable, allowing for versatile use at different points in the production line. AODD pumps therefore offer numerous advantages for the distillates industry, including:

- Gentle handling: the diaphragm pumps transfer the fluid gently, avoiding the risk of foaming or agitation that could alter the taste of the distillate.

- Low risk of cavitation: thanks to their ability to self-priming and the possibility of operating in deadhead conditions, AODD pumps guarantee uninterrupted operation.

- Easy maintenance: with few moving parts and a simple design, AODD pumps require little maintenance and are easy to repair, minimising downtime.

- Safety: AODD pumps can be grounded and are ideal for use with high alcohol content liquids or flammable vapours, ensuring safe operation even in potentially explosive environments.

Technical characteristics of Debem AODD pumps for distillates

Debem’s AODD pumps are designed to meet the most demanding requirements of the distilled spirits industry, thanks to advanced technical features that guarantee reliability and efficiency:

- Special food grade PTFE diaphragms: Debem diaphragms are made of food grade PTFE, supported by a layer of EPDM. This unique design prevents the formation of deposits and improves fluid flow, ensuring optimal product transfer.

- 316L stainless steel central block: The pump central block is made of mechanically polished 316L stainless steel for maximum corrosion resistance and ease of cleaning.

- Patented pneumatic heat exchanger: Debem pumps are equipped with a patented pneumatic heat exchanger that prevents stalling and reduces air consumption, ensuring high performance and long service life.

- Optical leakage detection sensors: pumps can be equipped with fibre-optic sensors that detect any damage to the membranes, preventing fluid leaks and immediately alerting the operator.

- Eccentric valves for solids passage: thanks to their eccentric profile valves, Debem pumps allow the safe passage of solids suspended in the fluid, making them ideal for distillates with suspended particles.

- Rotatable connections and quick emptying system: All connections are rotatable, allowing easy installation and a quick emptying system for cleaning and maintenance.

Discover Debem's solutions for optimising your distillery processes

Debem AODD pumps are the ideal choice for operators looking for reliability, safety and high performance in the distillery industry. Thanks to their advanced features and customisation possibilities, Debem’s alcohol transfer pumps fit perfectly in any distillery, helping you optimise the different stages of your production processes. Ask for a personal consultation with our sales team to find out how our solutions can improve the operating conditions of your distillery and ensure maximum quality and efficiency.