The secrets of pumps for the food industry

Pumps for the food industry are essential components of food production as they facilitate the safe and efficient transfer of various products during different stages of the production process. The use of high quality diaphragm pumps is essential to ensure that each stage of production takes place reliably, while maintaining high standards of hygiene and safety.

The importance of food pumps in production processes

In the food industry, diaphragm pumps play a key role in various applications, from raw material processing to final packaging. Here are some of the main production steps in which food pumps are indispensable:

- Ingredient handling: food pumps are used to transfer liquid or semi-liquid ingredients from storage areas to processing machinery. This includes the transfer of oils, syrups, milk and other ingredients that require gentle movement to preserve their quality and prevent contamination.

- Mixing and homogenising: food pumps ensure a constant and controlled flow of ingredients, allowing uniform mixing. This is essential for products such as sauces, creams and yoghurt, where uniform consistency is crucial for the final product quality.

- Filtration and separation: food pumps help transfer fluids through filtration systems, removing impurities or separating different components of the product, such as fats and oils. This step ensures that the final product meets food safety standards.

- Packaging and bottling: in these processes, pumps for the food industry enable the transfer of products into final containers. An example is the filling of juice bottles, jam jars or yoghurt packs. In this case, the pumps must ensure a constant and controlled flow, minimising waste and guaranteeing product safety.

- Cleaning and sanitising: to prevent contamination and ensure the quality of the end product. Food pumps are used to transfer detergent and disinfectant solutions, ensuring that all equipment is clean and ready for the next production run.

Essential requirements for pumps in the food industry

To operate in a sensitive and regulated environment such as the food industry, pumps must meet several specific requirements. Here are the main ones:

- Safe and certified materials: pumps must be made of food-compatible materials, such as 316L stainless steel, and must be certified according to international food regulations.

- Ease of cleaning: they must be designed to allow easy and thorough cleaning, with smooth surfaces and no corners where residues could accumulate.

- Corrosion and wear resistance: pumps must withstand wear and tear caused by acidic, alkaline products and varying temperatures, ensuring a long service life.

- Accuracy and reliability: they must guarantee precise dosing and continuous operation without interruptions, which is essential for maintaining consistent production cycles.

- Operational safety: they must be equipped with advanced safety systems, such as leak detection sensors, to prevent accidents and ensure the protection of workers and consumers.

The advantages of Debem pumps in the food industry

Debem pumps are designed to meet and exceed the most stringent requirements of the food industry. They offer a unique combination of innovation, efficiency and ease of use, making them the ideal choice for companies seeking reliable and safe solutions.

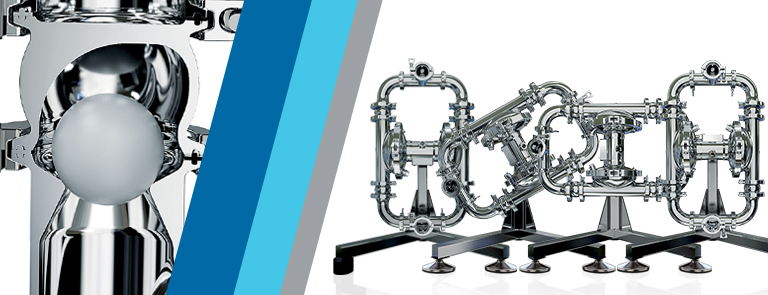

Thanks to special food-grade PTFE diaphragms supported by an EPDM layer, Debem pumps provide excellent resistance and optimised flow management, minimising the formation of deposits and improving operational efficiency.

The mechanically polished 316L steel core block not only offers superior corrosion resistance, but also facilitates cleaning and maintenance, which are essential for maintaining high standards of hygiene.

Debem pumps are also equipped with a patented pneumatic heat exchanger, a unique system in the market that prevents stalling, improving performance and reducing energy consumption. This component is particularly appreciated for its longevity and ease of maintenance.

For maximum safety, Debem pumps can be equipped with optical leak detection sensors, which constantly monitor the integrity of the membranes and automatically stop the pump in the event of faults. This advanced system protects the system and prevents product damage.

Finally, eccentric valves allow the safe passage of solids suspended in the fluid, while rotatable connections and a quick-emptying system provide unparalleled operational flexibility, facilitating cleaning and sanitising operations.

To find out more about Debem’s solutions for the food industry and how they can improve the efficiency and safety of your production, contact our sales team.