Company profile

A leading company specialising in the production of artisan crêpes and pancakes contacted us with an urgent request: to efficiently manage a production peak expected on Pancake Day. The company, which has been operating in the food sector for many years, is renowned for the high quality of its products and its attention to health and hygiene regulations in production.

- CUSTOMERArtisanal crêpe and pancake manufacturer

- INDUSTRYFood

- SOLUTIONPancake batter pump

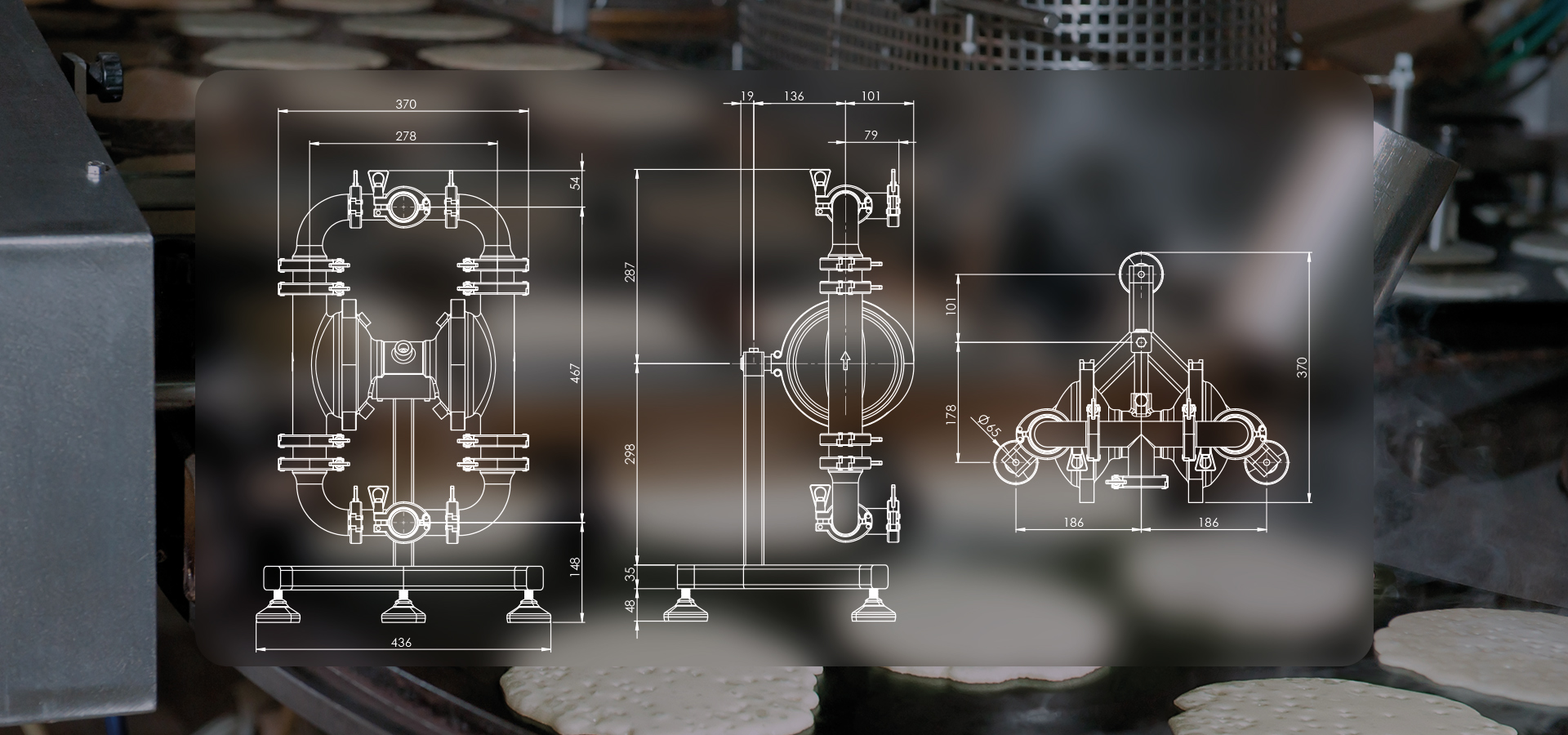

- MODELAISIBOXER 02

AISIBOXER-02 Application of the pancake batter pump

The company needed an effective solution to transfer pancake batter from the mixer to the holding tank efficiently and without altering the characteristics of a product that is both highly viscous and sensitive to shear.

Following a thorough technical evaluation, the DEBEM AISIBOXER-02 AODD pump was identified as the most suitable choice—thanks to its ability to handle delicate food products with care, while ensuring consistent and reliable transfer throughout the process.

Hygienic cleaning of the food dough pump

The AISIBOXER-02 food dough pump is designed to meet the highest hygiene standards. The cleaning process consists of three different stages:

- Quick removal of the 1 ½" Tri-Clamp connections, allowing immediate access for maintenance.

- Internal washing with specific detergents for the food industry, hot water and, if necessary, steam to remove all residues.

- Final rotation of the pump to facilitate complete drainage of liquids and ensure effective and safe drying.

This procedure ensures impeccable hygiene and reduces downtime, contributing to continuous, compliant production.

Continuous use of the viscous food pump

The AISIBOXER-02 viscous food pump is used daily throughout the intensive production week leading up to Pancake Day. Its robustness and reliability allow for continuous use without interruption, ensuring consistent performance even under particularly demanding working conditions.

Why choose a batter transfer pump such as the AISIBOXER-02?

The transfer of viscous and shear-sensitive mixtures requires reliable, hygienic solutions designed to preserve the characteristics of the product. The AISIBOXER-02 pump has been developed to meet these requirements in food production, offering a combination of robustness and precision.

- FDA – MOCA certified, with body and manifolds made of mechanically polished AISI 316 L stainless steel (roughness <0.8 microns), compliant with the most stringent health and hygiene requirements.

- High compatibility with viscous products, such as pancake batter, ensuring gentle transfer and preservation of product structure.

- Hygienic design, compatible with CIP washing cycles, for effective and quick cleaning at the end of production.

- Reduced maintenance costs, thanks to fewer components subject to wear, up to 50% less than traditional alternatives.

AISIBOXER-02 represents a strategic technical choice to improve the efficiency of food processing plants, reduce machine downtime and ensure production continuity even under intense working conditions.

Operational advantages with a food dough pump

The adoption of the AISIBOXER-02 AODD dough pump brought measurable improvements to the pancake dough production line. Its performance allowed the company to handle peaks in demand with consistent output and precise process control.

- Enhanced efficiency in dough transfer, ensuring a smooth and continuous flow

- Improved production stability and consistent product quality across batches

- No more issues with changes in dough texture during pumping

- Shorter maintenance intervals and lower operating expenses

- Better flow regulation and seamless adjustment to varying production volumes

These outcomes clearly demonstrate how a pump designed for viscous and delicate food products can make a significant difference in both the performance and dependability of food manufacturing systems.