Six tips for optimizing the use of a food pump

Within this article we want to focus attention on ways to optimize a food pump in a competitive scenario where the focus of food manufacturers is constantly on improving production processes to optimize resources, reduce costs, and increase profits. The equation, however, is by no means simple in this application context. Saving resources or limiting investment in technology could reduce the focus on the most important aspect of this industry namely maintaining high hygienic conditions that preserve food products from risks of contamination or mishandling and subsequent spoilage. However, by adopting a set of best practices, processes can be optimized, costs kept under control, and risks associated with food handling and transfer reduced.

1) Choosing a proper food pump

The biggest concern for food manufacturers is ensuring high standards of hygiene within production processes. However, just like other businesses, food businesses must remain profitable. Therefore, in addition to cleanliness, companies also focus on minimizing product waste and maximizing energy efficiency. Choosing the right equipment is the basic starting point for any intervention to optimize the production process. Pumps are among the most important pieces of equipment in food and beverage processing. In addition to having to handle loading, unloading and transferring functions of low and high viscosity fluids, food pumps must be able to operate efficiently over a wide range of temperatures, adequately handle cleaning and sanitizing processes while ensuring protection from contamination risks.

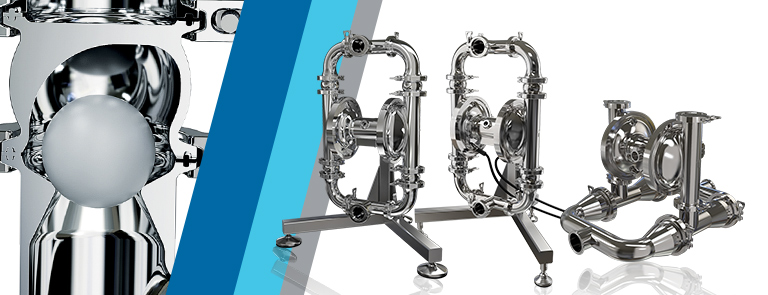

By choosing Debem’s line of food pumps, all food processing needs can be met while keeping energy costs and any risks of spoilage and contamination under control.

2) Choosing food grade pump materials carefully

In addition to choosing the correct pumping application, it is necessary to pay attention to other factors, including the choice of construction materials. Careless choice can cause an adverse chemical reaction between the pump materials and the pumped fluid causing corrosion damage. When corrosion occurs, pump efficiency and performance can be drastically compromised and, in extreme cases, can lead to pump failure. To avoid corrosion, it is necessary to choose a pump with materials of construction compatible with the fluid to be handled. In addition, for food applications, the pump must be hygienic and easily cleaned.

The central body of Debem hygienic pumps is made from a single block of 316 L steel machined from molds, mechanically polished with a Ra < 0.8 µm surface finish. This material is particularly suitable for handling and transferring food products. In contrast, Debem pump diaphragms have a food-grade PTFE cover and a food-grade EPDM layer. This type of diaphragm provides high resistance to mechanical stress and at the same time a long service life.

3) Control the risks of food processing pump cavitation

Pump cavitation is a very common problem in food centrifugal pump use. The phenomenon of cavitation occurs when the liquid pressure drops below the vapor pressure. The pressure reduction, followed by condensation, forms bubbles at the inlet of the impeller that implode on the discharge side of the pump. These micro-jets damage the internal parts of the pump, disrupting the flow and causing the seals to fail.

Debem pumps employ a patented coaxial pneumatic anti-stall exchanger that introduces compressed air to alter the pressure balance of the diaphragms. The presence of an anti-stall circuit ensures optimal performance even under the most critical conditions. The control (spool) and power (exchanger) parts are placed in a single block inside the pump. This housing system further limits pressure drops as compressed air flows into the pump.

4) Keeping leak risks under control

Within production processes that involve the transfer of expensive fluids such as those used in the food industry (e.g., wine, beer, food sauces, oils, and condiments), leak detection devices are crucial because they allow monitoring of membrane integrity through visual, electronic, or mechanical leak detection systems.

Food and beverage pumps manufactured by Debem are equipped with special sensors that can detect membrane rupture and automatically stop pump operation. The sensors, located on the bottom of the pump close to the membranes, greatly reduce the risk of product contamination during transfer processes.

5) Efficiently ensure sanitization and cleaning processes.

An extremely important process within the food industry is cleaning in place (CIP) that allows pumps to be cleaned in an automated manner without the need to disassemble parts and resort to manual operations. In order to produce a high-quality product with reasonable costs, a reliable and efficient cleaning system for process equipment must be adopted.

The Rapid Emptying System, found inside Debem sanitary pumps, allows complete emptying of the fluid inside the pump chambers. The operation can be conveniently done by hand without the use of tools or special equipment. The pump will then be free of internal impurities and ready to be flushed and sanitized.

6) Keep the wear and tear on the pump under control through thorough checks and regular maintenance

As with all equipment, wear and tear is inevitable during the operation of a pump, resulting in reduced performance. In addition to prolonged use, wear can be caused by problems with proper pump sizing or low compatibility between pumped fluid and pump material. Following a proper pump maintenance program that ascertains proper installation conditions can slow the rate of pump wear.

Debem also suggests making sure that the pump size and materials are suitable for the production application and the fluid to be handled. If you need further information, our sales team will be ready to support you in selecting the best pumping equipment suitable for your specific needs.