The new line of Debem hygienic pumps

Debem has created a new line of hygienic pumps suitable for the transfer of fluids in the food, beverage, pharmaceutical, cosmetic and hair care sectors. This new line of pneumatic double diaphragm pumps (AODD) features materials that comply with 3A, MOCA and FDA specifications. These certifications allow the use of Debem pumps in food processing and personal care products.

The strict regulations and production requirements for these application sectors demand the highest quality products. In this context, Debem, thanks to over 30 years of experience and a portfolio of miles of satisfied customers around the world, offers itself as a privileged partner for the supply of pumps for handling fluids, even with high viscosity and with solid parts in suspension.

The product line of the Hygienic series includes extremely versatile double diaphragm pneumatic pumps capable of safely and efficiently handling a wide range of fluids with variable viscosity.

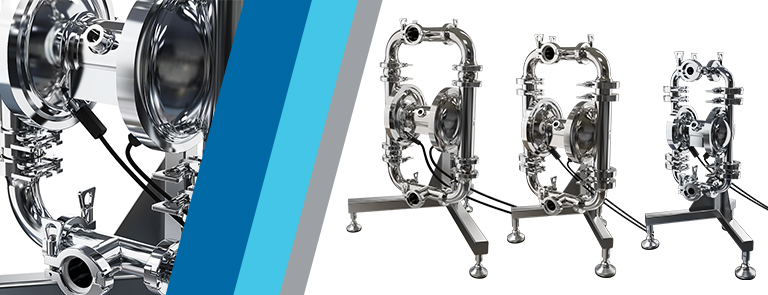

Debem has created 3 families of AODD pumps aimed at supporting the different requests of the target sectors.

AISIBOXER pumps

AISIBOXER are double diaphragm volumetric pumps operated by compressed air intended for the food and beverage, cosmetic and trichological sectors. AISIBOXER pumps are undergoing MOCA and ATEX certification and are FDA Compliant.

The pumps from the AISIBOXER line are built in mechanically polished AISI 316 L with a surface finish of less than <0.8 μm. An important feature of the AISIBOXER pumps is the Quick Emptying System which allows for complete manual emptying of the fluid present inside the product chambers.

AISIBOXER pumps can be equipped with eccentric fluid ball valves. Their constructive form differs from normal ball valves as it allows to convey fluids with larger suspended solids.

SANIBOXER pumps

SANIBOXER are double diaphragm pneumatic volumetric pumps suitable for handling fluids in sectors such as the pharmaceutical, cosmetic and trichological industries: they are an optimal solution for the transport of liquids and fluids with high apparent viscosity, even in the presence of suspended solid parts.

The pumps from the SANIBOXER line are built in mechanically polished AISI 316 L with a surface finish of less than <0.8 μm.

SANIBOXER pumps are equipped by default with sensors to detect the rupture of the membranes in order to avoid contamination during the transfer processes. SANIBOXER pumps also feature the Quick Emptying System which allows the pump to completely empty the fluid present inside the product chambers.

SANIBOXER pumps are undergoing 3A, MOCA and ATEX certification.

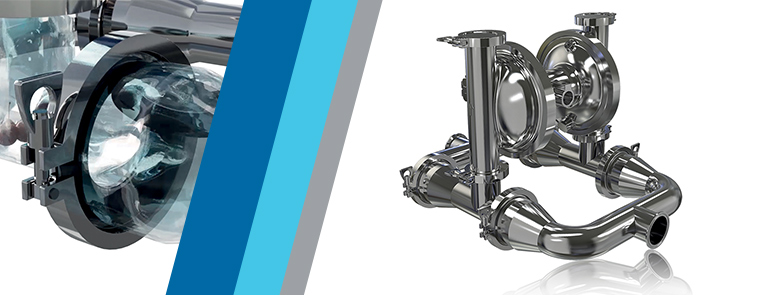

FULLFLOW pumps

FULLFLOW is the line of volumetric compressed air pumps for the food, meat and poultry sectors, suitable for handling liquids and fluids with larger suspended solids.

FULLFLOW pumps are built in mechanically polished AISI 316 L with a surface finish lower than <0.8 μm. All the features of the FULLFLOW pumps comply with the requirements of the FDA regulations.

The FULLFLOW pump, unlike the models on the market which usually have a vertical hydraulic circuit, preserves the contact of the solid elements with the membranes avoiding problems of wear from cutting or rubbing and greatly increasing their life.

FULLFLOW pumps have special valves whose flaps open and close allowing a complete passage of suspended solids and obviously the non-return of the fluid itself, having a forced position in their movement.

The main advantages of DEBEM pumps

Special membranes

The membranes of DEBEM pumps are composed of a layer of EPDM – air side and a part in food-grade PTFE in contact with the fluid, which allows to avoid the formation of product deposits, helping the movement of fluids.

Patented pneumatic exchanger

All Debem Hygienic pumps are equipped with a patented pneumatic exchanger that guarantees superior performance with reduced air consumption: a long-lasting device that makes maintenance operations extremely easy.

Central Block

The central body of the Debem Hygienic pumps is composed of a single block of 316 L steel obtained from a mold, mechanically polished with a surface finish Ra <0,8 µm.

Optical sensors

Debem Hygienic pumps can be equipped with special fiber optic sensors to detect any damage to the membranes, with consequent fluid leaks. In the event of a malfunction, the sensors warn the operator and automatically stop the operation of the pump.

Rotatable connections and quick emptying system

All connections of Debem Hygienic pumps are rotatable and allow extreme freedom of installation on the system. The pumps are installed by default on a special stand which allows them to rotate at 360 °, suitable for quick emptying of the product during the washing and sanitizing phases.

Conclusion

Debem SRL designs and manufactures double diaphragm pneumatic pumps suitable for use in the food, beverage, pharmaceutical, cosmetic and hair care sectors. Debem Hygienic pumps for these sectors are made of materials that meet 3A, MOCA and FDA specifications. DEBEM sales engineers can support you in choosing the best solution in terms of configuration, size and materials. Contact the DEBEM team now for more information.