Milk Dairy Pumps: Let's find out the benefits

Milk dairy pumps represent a technology that is constantly evolving to ensure operational performance and safety standards aligned with the demanding requirements of the industry. In fact, production facilities in the dairy sector require automated processes aimed at enabling safe transport of the product by minimizing the risks of leaks or residues remaining inside the plant.

These are the reasons why people in the industry have chosen pumping technologies involving the use of pneumatic double diaphragm pumps, a technology that provides efficient and reliable performance in many application areas.

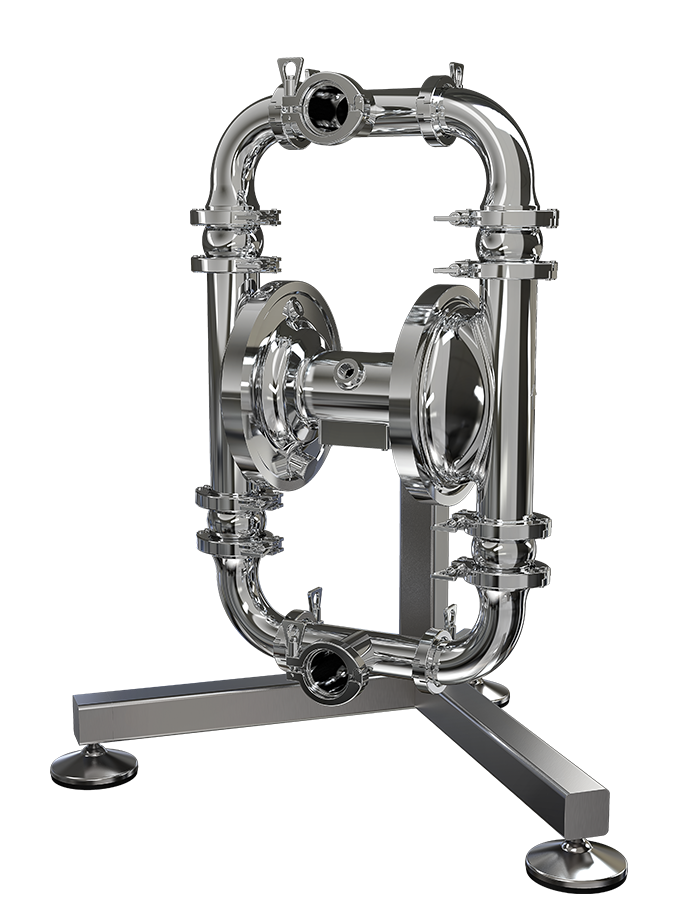

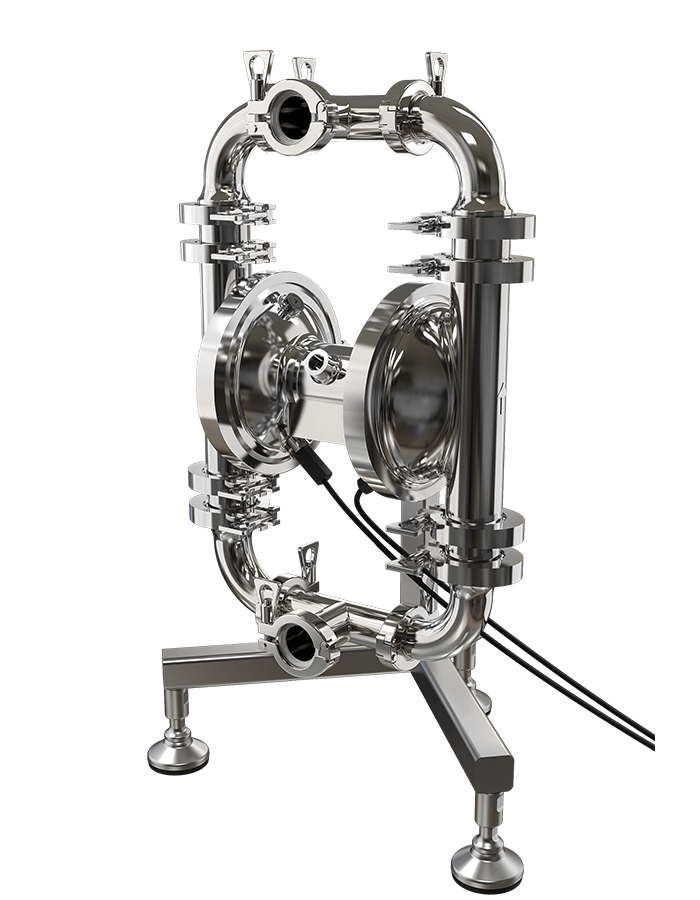

Double diaphragm pumps for dairy industry

AODD pumps are suitable for use in numerous applications in the dairy industry, including the transfer, mixing and dosing of ingredients and raw materials, drum filling and emptying, and plant recirculation operations. Dairy double diaphragm pumps are also capable of handling viscous liquids and fluids containing suspended solids. This versatility makes them particularly suitable for pumping different types of liquids including cottage cheese cream, cream, ice cream mixtures, syrups and toppings, yogurt, margarine, butter and other fats.

The advantages of AODD technology in milking pumps

The advantages of using double membrane pumps in the dairy industry can be summarized in the following points.

- Design configuration: the configuration of an appropriately spaced through-flow within the pump promotes the transfer of viscous liquids or fluids with solids without the risk of generating clogging in the pump and consequently operational blockages in the system.

- Shear sensitivity: AODD pumps promote a gentle pumping action that avoids damage to shear-sensitive products. When transferring highly viscous liquids, the pumping speed is automatically reduced to a stop (when liquid conditions no longer allow for transfer) while avoiding the risks of pump damage.

- Self-priming capability: the double diaphragm pump is capable of drawing liquid when placed above the level of the fluid to be pumped. This advantage makes the pump usable in several placement scenarios.

- Ability to work dry: if during the pumping action the liquid runs out, the pump retains the ability to work dry without generating any damage to its internal parts.

- No electricity: AODD pumps are powered entirely by compressed air and can therefore be used in applications where electricity is not available or cannot be used.

- Low maintenance costs: double-diaphragm pumps generally consist of a small number of elements. The membranes are easily disassembled and replaced. These factors help to keep maintenance costs low.

Adaptation of Debem milk dairy pumps to hygienic and sanitary regulatory requirements

The hygienic pumps for milk products manufactured by Debem, in addition to the advantages listed in the preceding paragraphs, have an important application benefit arising mainly from the materials used in their manufacture.

Specifically, the Debem hygienic pump body is composed of a single block of mechanically polished 316 L steel with Ra < 0.8 µm surface finish. The diaphragms, on the other hand, are lined with a food-grade PTFE part in contact with the fluid, supported by a layer of EPDM. These materials enable the pump to operate efficiently and reliably while reducing the risk of damage (e.g., when in contact with abrasive liquids) or contamination of the product (e.g., when liquid meets pump parts). The resistance of these materials to aggressive chemicals also enables the pump to support CIP (cleaning in place) processes without the risk of wear or damage. The use of these materials also enables Debem hygienic pumps to comply with the industry’s most important certifications such as the FDA (Food & Drug Administration), 3A (Sanitary Standards Administrative Council) and MOCA.

How to choose a milk dairy pump

Debem offers a high selection of pumps suitable for supporting liquid production and transfer processes within the food industry. Debem’s technical sales team is available in supporting with application advice the selection of the most suitable pump for a given application within the allocated budget.