Sauce pumps: practical guide to selection and hygienic integration

The transfer and handling of fluids within food production lines can alter the structure, color, and aromatic profile of the various ingredients involved in the production process. The wrong choice of pump introduces air, can alter the ingredients, promotes the separation of the oily part, and lengthens washing times. Purpose-built, low-shear, hygienic sauce pumps keep flow under control and emulsions stable while enabling fast, repeatable sanitation (CIP) cycles. This article outlines the key risks, the criteria for configuring an appropriate system, and the variables that should guide your purchasing decision.

What are the risks of using an unsuitable sauce pump?

Transferring high-viscosity sauces puts a strain on materials, geometries, and pumping principles. Excessive turbulence and high mechanical shear conditions generate aeration and foam, destabilize the emulsion, and damage the inclusions.

The effects are visible to the naked eye: uneven texture, premature oxidation, packaging waste, and reduced shelf life. On the hygiene front, rough surfaces and the use of seals that are not suitable for food contact can lengthen cleaning cycles, complicate audits, and increase the risk of cross-contamination between batches.

Operationally, a sauce pump must handle frequent starts, complete tank emptying, and rapid recipe changeovers. If it cannot self-prime or struggles during transients, Overall Equipment Effectiveness (OEE) drops and your cost per kilogram transferred rises.

The right pumping solution for sauces and condiments

A pumping configuration that combines product quality and plant efficiency is based on four pillars:

- Materials and finish: body and contact parts in AISI 316L with a mechanical finish typically Ra ≤ 0.8 μm improve hygiene and cleanliness. Smooth surfaces, wide curves, and fittings without edges reduce stagnation areas and speed up washing.

- Connections and removability: Tri-Clamp fittings enable rapid inspections and changeovers, while a drainable design maximizes gravity product recovery and shortening CIP cycles and reducing waste.

- CIP (Clean-In-Place) compatibility: design that allows internal cleaning of pumps and pipes without dismantling, using standardized sequences of pre-rinsing, washing with suitable detergents, and final rinsing with hot water; guarantees reliable times and repeatable results, facilitates traceability (time, temperature, concentration, flow rate), and reduces the risk of cross-contamination.

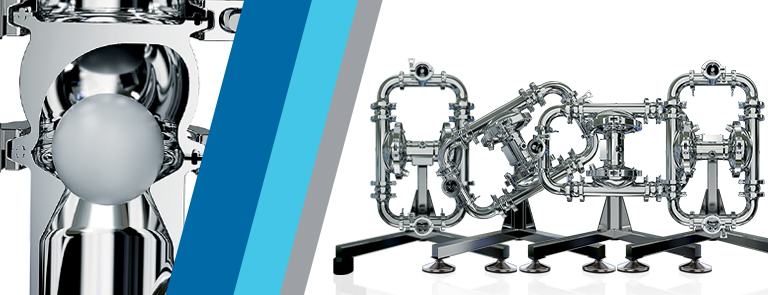

- Low shear pumping principle: AODD (air-operated double diaphragm) hygienic pumps are widely used in industrial kitchens for thick sauces as they offer significant advantages in terms of self-priming, tolerance to dry running for short periods, passage of particles without damaging them, and fine adjustment of flow rate via air pressure/flow.

Practical example: when transferring Genoese pesto, these criteria allow the structure and flavor to be preserved, with quick washing between batches.

How to choose a pump for sauces and condiments?

Choosing the right technology affects fundamental elements such as product quality, documentable hygiene, and cost per kg transferred. Before comparing models, collect key data about your recipe and your system: this is the only way to accurately size the pump and prevent downtime, waste, and endless washing. The following is a clear, complete operational checklist.

- Know your sauce. Record its viscosity at working temperature, particle diameter/fragility, oil content, and sensitivity to shearing. This will determine the principle, size, and choice of elastomers (EPDM, FKM, PTFE based on pH, detergents, temperature).

- Plan hygiene upstream: consider the use of AISI 316L materials, Ra ≤ 0.8 μm, absence of dead legs, Tri-Clamp, drainage path. Define the CIP recipe compatible with your shift schedule.

- Check integration: required flow rate and head, compressed air quality/availability, pipe layout, maintenance space, safety sensors (e.g., membrane rupture detection), ATEX requirements for alcoholic recipes or classified areas.

- Test on the actual product: conducting trials with actual batches, containers, and operating temperatures is the fastest way to validate yield, washing times, and set-up parameters before investing.

Turn selection criteria into measurable results. Debem’s technical and sales team will help you choose the right sauce-pump model, specify materials and configuration, and optimize your line, cutting downtime, improving yield, and standardizing cleaning (CIP) cycles. Contact us for a technical evaluation.