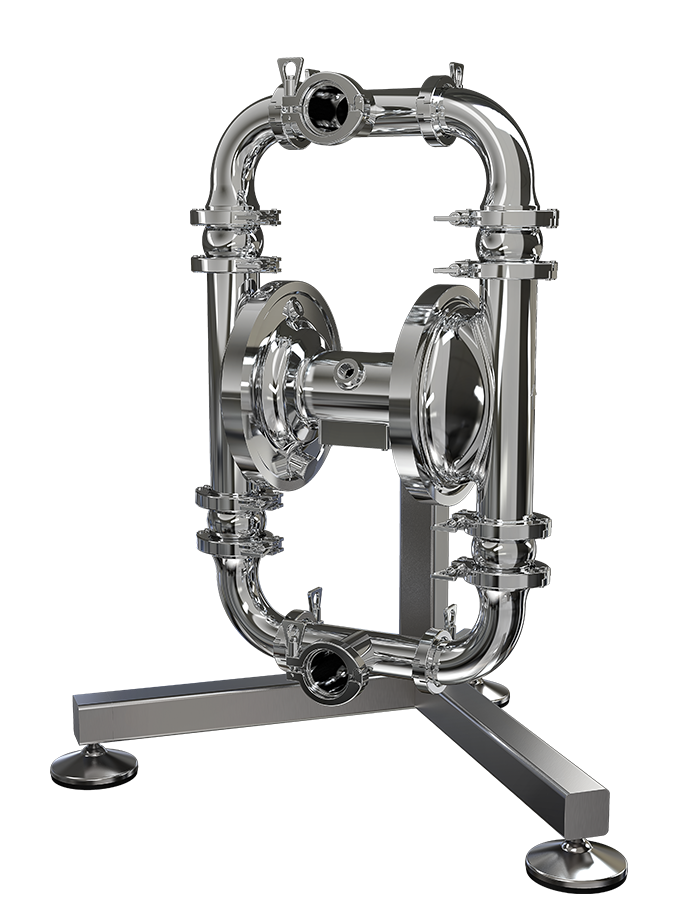

The hygienic line of double diaphragm pumps

Our “Hygienic” product line includes extremely versatile air-operated double diaphragm pumps capable of handling a wide range of fluids with variable viscosity safely and efficiently.

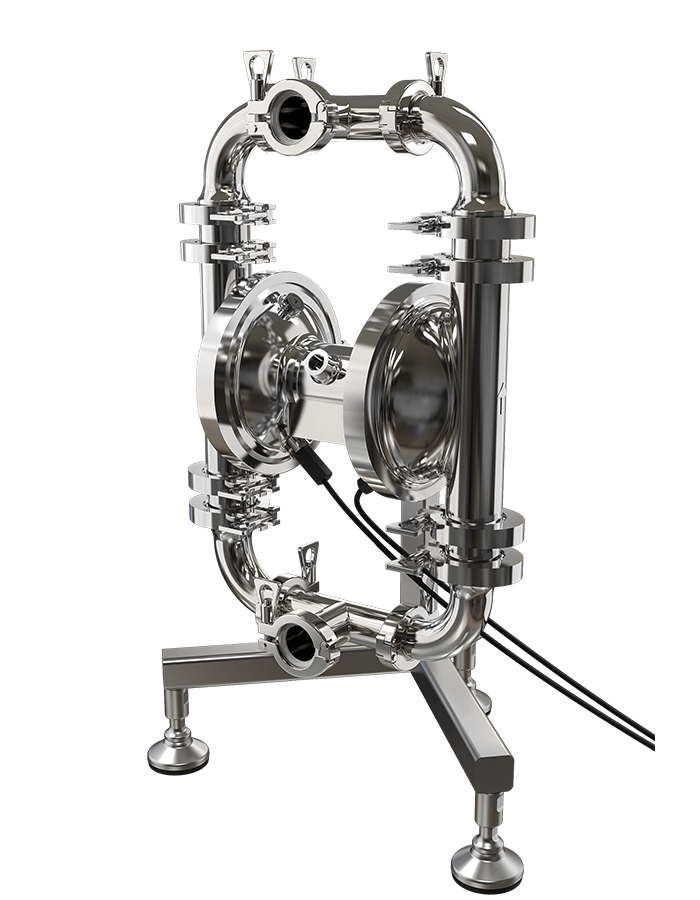

DEBEM diaphragms are composed partly in food-grade PTFE for contact with the fluid, supported by a layer of EPDM. The unique surface shape and absence of anchoring caps prevents the formation of product deposits and at the same time helps fluid movement by improving flow.

All Debem Hygienic pumps are equipped with a patented pneumatic exchanger, an anti-stall system unique to the market, which guarantees superior performance with reduced air consumption. This long-life device consists of a very small number of components, which makes maintenance extremely easy.

The central body of the Debem pumps is composed of a single block of 316 L steel obtained from a mould and mechanically polished with a surface finish Ra < 0.8 µm.

Debem pumps can be equipped with special fibre optic sensors to detect any diaphragm damage that may cause fluid leakage. In case of malfunction, the sensors warn the operator and automatically stop pump operation.

Debem pumps can be equipped with special ball valves with an "eccentric" internal profile, which allow the passage of large solids suspended in the fluid.

All connections are rotatable and allow maximum freedom of system installation. The pumps are installed by default on a special stand which allows them to rotate at 360° for quick emptying of product when washing and cleaning.

The different target sectors of the Hygienic range

Discover all the possible applications of Debem pumps in the application sector overview. Each pump has its own perfect fit and can carry out the most demanding fluid handling applications, even with high viscosity and suspended solids.