How can AODD pumps improve carbonated beverage production processes?

The non-alcoholic beverage market is characterized by the presence of plants, operated by multinational or third-party companies, used for preservation and bottling through a production flow that involves the processing of particular ingredients, including corn syrup, fructose, various concentrating substances, flavorings and phosphoric acid. The result of the production process is the soft drink that is marketed in stores and made available to end consumers.

What these soft drink production operations have in common is strict adherence to strict production protocols so that the finished product lives up to the brand’s taste and regulatory-hygienic standards of the industry.

The production process of soft drinks

A pattern that unites the production processes of soft drinks can be described in the following points:

- The common water, used in the composition of the beverage, is treated to remove any impurities that may alter the taste or color.

- The next step involves sterilizing the treated water to destroy any residual bacteria or organic compounds.

- The sterilized water “rests” in a storage tank and flows through an activated carbon filter that performs a dichlorination operation.

- This is followed by the addition of a premixed concentrate substance that is pumped to a dosing station, where it is combined with the water

- This concentrate/water mixture moves to a “batch” tank where it is mixed to form the base of the soft drink and then pasteurized instantaneously.

- The mixture passes through a carbonator that adds carbonation at predetermined levels according to the soft drink recipe

- The finished product is transferred to the filling lines where it is injected into bottles and cans later packaged in cartons or trays for shipment to distributors.

Advantages of AODD pumps in beverage production

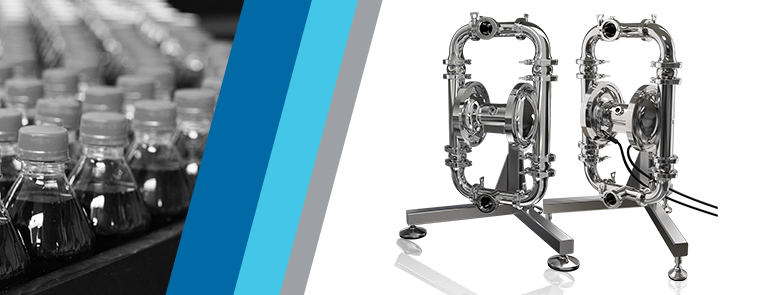

The line of AODD food pumps designed by DEBEM offer several operational advantages that make them more suitable for soft drink production than centrifugal pumps. The main operational advantages of AODD pumps in beverage production are as follows:

- Simplified design: The simplicity of AODD pumps makes them very attractive to the beverage industry. “Plug in and play” functional features combined with a highly effective ability to pump most substances makes them the pump of choice for many in the industry.

- Ability to run dry and self-priming: the double diaphragm pump will not be damaged when operating without fluid. In addition, they are able to suck in fluids even when the pump is not potted.

- Chemical resistance: double diaphragm pumps do not involve direct contact of the components with the liquid to be conveyed. Thus, the diaphragm pump can smoothly handle liquids that are not perfectly filtered or have residual solid particles or acids, solvents and abrasive particles.

- Safety: Because AODD pumps use compressed air as their sole power source, they are intrinsically safe and are available ATEX certified for use in applications where electricity cannot be used.

The Aisiboxer and Saniboxer food pumps offer the ability to pump a wide range of viscosities and shear-sensitive products and are perfect for handling corn syrups, phosphoric acids, concentrates and flavorings, all of which are critical in soft drink production. Their high versatility of operation and design features make them the right solution for the industry. In particular, the mechanically polished ASISI 316 L material is particularly important for handling food substances according to strict industry regulations.

The use of centrifugal pumps within the beverage industry

Centrifugal pumps have been a staple within the beverage production industry for many years. However, although characterized by lower purchase costs, they can have operational inefficiencies with subsequent higher lifetime costs. For example, centrifugal pumps are not self-priming, may falter when pumping high-viscosity liquids, are unable to run dry, have mechanical seals that are prone to leakage, and are driven by electric motors that must be kept dry during operation.

Conclusion

DEBEM’s line of food pumps is an optimal choice for the many points of liquid processing and handling within a soft drink packaging plant. The use of DEBEM’s AODD pumps can help achieve high product quality standards while reducing operating and maintenance costs. Contact our sales team for more information.