Optimization of the production process

AISIBOXER-03 / Sauce pump ideal for transferring pesto alla Genovese

DISCOVERCompany Profile

In the food industry, companies must respond to increasing demands for both quality and productivity. By adopting advanced technologies like the AISIBOXER 03 pump, they can effectively address key challenges related to the transfer of high-viscosity products. Backed by proven industry experience, the company chose to integrate solutions that combine efficiency and sustainability, delivering tangible improvements across the entire production line.

- CUSTOMERItalian company producing artisanal sauces and condiments

- SECTORProduction of sauces, seasonings and preparations for gastronomy.

- SOLUTIONGenoese pesto pump

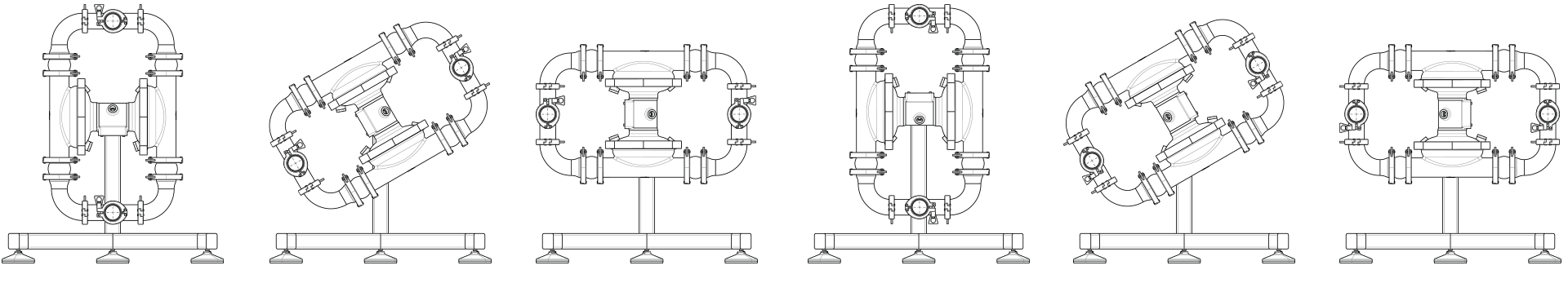

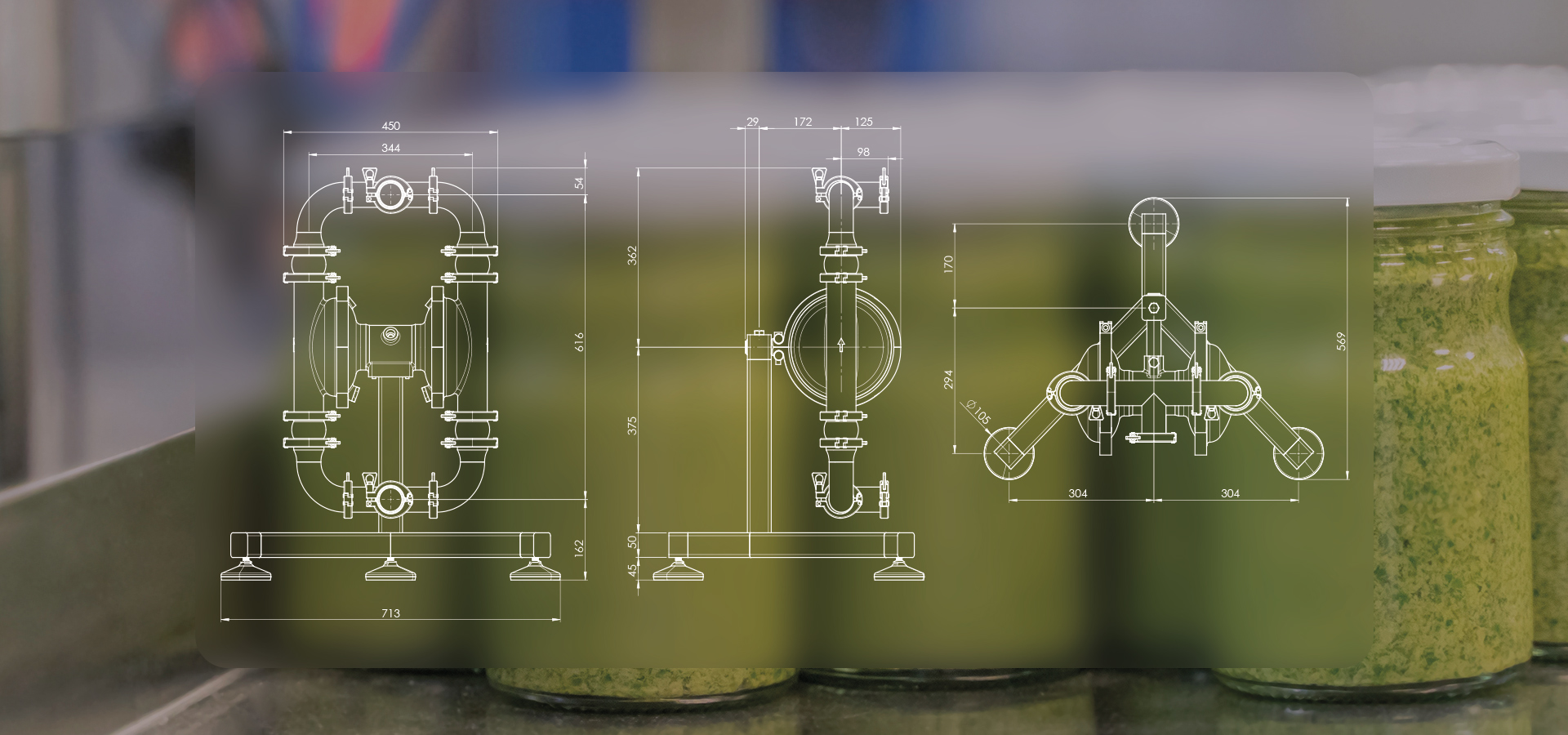

- MODELAISIBOXER 03

Application of the AISIBOXER-03 pump

The AISIBOXER 03 pump was adopted to optimize the transfer of sauces and other products such as pesto alla Genovese. With its advanced technology, it has improved process efficiency, reducing downtime and minimizing waste. It has been integrated into two key stages of food production:

- Sauce transfer. The pump enables gentle and accurate transfer of pesto, preserving its consistency and quality throughout the process, without compromising its organoleptic properties.

- Flexible raw material handling. Designed for versatility, the pump adapts easily to different plant configurations. Its ability to draw product from alternative containers helps streamline workflows, enhance operational flexibility, and reduce production stoppages.

Cleaning procedure

Cleaning the AISIBOXER 03 pump is essential to ensure maximum hygiene and prepare the system for the next production cycle. The cleaning procedure involves:

- Replacement of transfer tubes with those dedicated to the cleaning cycle.

- Use of specific detergents for sanitizing food machinery, hot water and steam for thorough cleaning of each component.

- After the wash cycle, the pump is rotated to remove any residual liquid, ensuring perfect drying.

Frequency of use

The AISIBOXER 03 pump is in operation daily, five days a week, handling the transfer of pesto alla Genovese and other sauces. Its robust construction and proven reliability support continuous use, ensuring a consistent, high-quality flow without impacting the efficiency or integrity of the production process.

Why AISIBOXER-03?

The company selected the AISIBOXER 03 pump after analyzing several solutions for transferring high-viscosity sauces. The choice was driven by the pump’s high efficiency, its ability to maintain a gentle, non-disruptive flow, and the preservation of the product’s original characteristics. Its easy maintenance and full compliance with hygiene regulations were also key factors, making the AISIBOXER 03 a perfect fit for the company’s operational and quality requirements.

Achievements

With the adoption of the AISIBOXER 03 pump, the company has seen a significant improvement in productivity and quality. The pump has contributed to a reduction in downtime, enhanced process reliability, and more streamlined production management. Its compliance with hygiene regulations ensures the company maintains high food safety standards, while its versatility has helped optimize workflows, reduce product waste, and improve overall operational efficiency.