Company Profile

A manufacturer of handmade hair gels and cosmetics faced a significant increase in demand for its premium products. To ensure efficient and hygienic transfer of gels during production, the AISIBOXER-03 pump was chosen, capable of handling viscous products without compromising quality and safety. The company operates in the cosmetics sector, complying with strict FDA and MOCA standards, and adopts hygienic and sustainable production processes.

- CUSTOMERManufacturer of hair gels and cosmetics

- SECTORCosmetics and dermocosmetics industry

- SOLUTIONPump for gels and cosmetic products

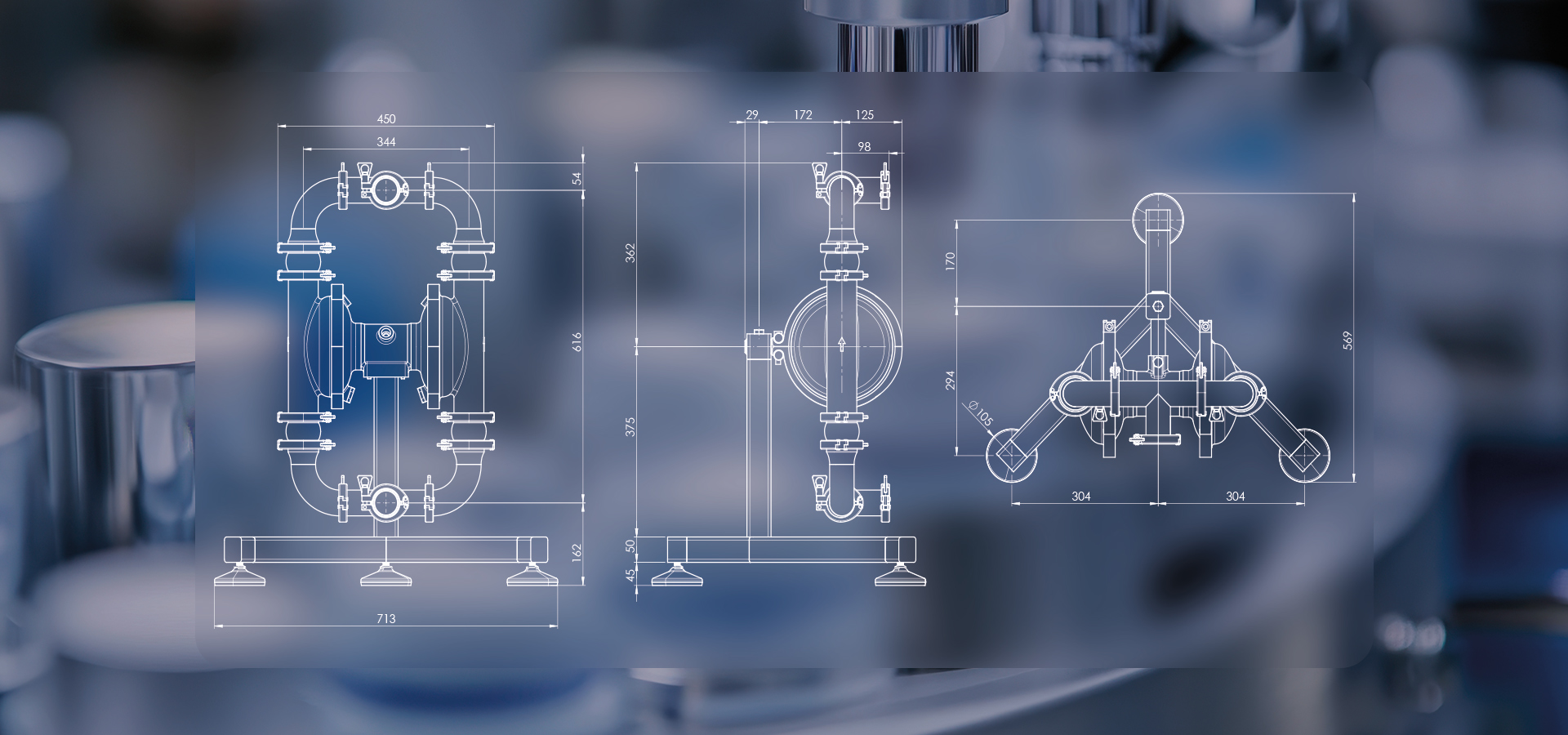

- MODELAISIBOXER 03

Application of the AISIBOXER-03 gel pump

It was necessary to transfer gels and cosmetic products from the tank to the filling machine without altering their consistency or contaminating the product. The gels, which are highly viscous and sensitive to shear, required smooth, continuous and safe transfer. After an in-depth technical analysis, the AISIBOXER-03 AODD pump was selected, as it is ideal for hygienic cosmetic applications and compatible with viscous and delicate products.

Cleaning procedure for gel and cosmetic pumps

The pump is designed to meet the highest hygiene standards. Cleaning is carried out by:

- Quick disassembly of 2" Tri-Clamp connections for easy maintenance

- Washing cycle with specific detergents for cosmetic use, hot water and, if necessary, steam

- Rotation of the pump to remove any liquid residue, ensuring complete drying and preventing contamination

Frequency of use of the AISIBOXER-03 cosmetics pump

The pump is used daily in the production of hair gels with intensive use.

- Standard shifts: 8 hours per day, 5-6 days per week.

- Production peaks: up to 12 continuous hours during periods of high demand.

- Continuous reliability: thanks to its robustness and easy maintenance, the pump can operate continuously, minimising downtime for washing and sanitising.

Why choose this pump for gels and cosmetic products?

The choice of the AISIBOXER-03 meets the specific needs of cosmetics production:

- Compatibility with high-viscosity gels: hair gels must be transferred without cutting or altering the consistency of the product.

- Absolute hygiene: mechanically polished 316L stainless steel body and FDA-compliant membranes ensure safe contact with cosmetic products, preventing contamination.

- Quick and easy cleaning: the hygienic design allows for fast CIP or manual cleaning cycles, reducing downtime between different batches.

- Reliability during production peaks: the pump withstands intensive shifts and production peaks without interruption, ideal for meeting seasonal increases in demand.

- Reduced operating costs: fewer wear components mean easier maintenance and lower costs without compromising performance.

Results obtained with the AISIBOXER-03 gel pump

The adoption of the AISIBOXER-03 pump has made it possible to achieve:

- Smooth and safe transfer of hair gels: the product maintains its consistency and quality without risk of cutting or contamination.

- Increased productivity: constant and reliable flow reduces waiting times and increases the number of batches that can be processed daily.

- Reduction in machine downtime and maintenance times: the hygienic design and durable membranes reduce technical interventions and operating costs.

- Better control of the production process: the pump allows variable volumes to be managed with precision, adapting to seasonal peaks in demand.

- High hygiene standards: ensures FDA compliance and safety in contact with sensitive cosmetic products.

- Waste reduction: efficient transfer without residues in pipes or tanks.