Company Profile

Founded with the goal of bringing Italian dairy excellence to the world, the company is now a reference point in the production of fresh cheeses and dairy specialties. With over 30 years of experience, it is one of the most established players in the sector, specializing in the production of burratine, mozzarella, and other dairy delicacies, producing more than 10,000 tons of product every year. Thanks to the use of innovative technologies and a careful selection of raw materials, the company guarantees products of the highest quality, complying with European and international food safety regulations. With a distribution network covering both the national and international markets, the company is present in over 20 countries, exporting Italian dairy tradition worldwide.

- CLIENTLeading company in the production of fresh Italian cheeses

- INDUSTRYDairy industry, specializing in fresh cheeses

- SOLUTIONDairy pump

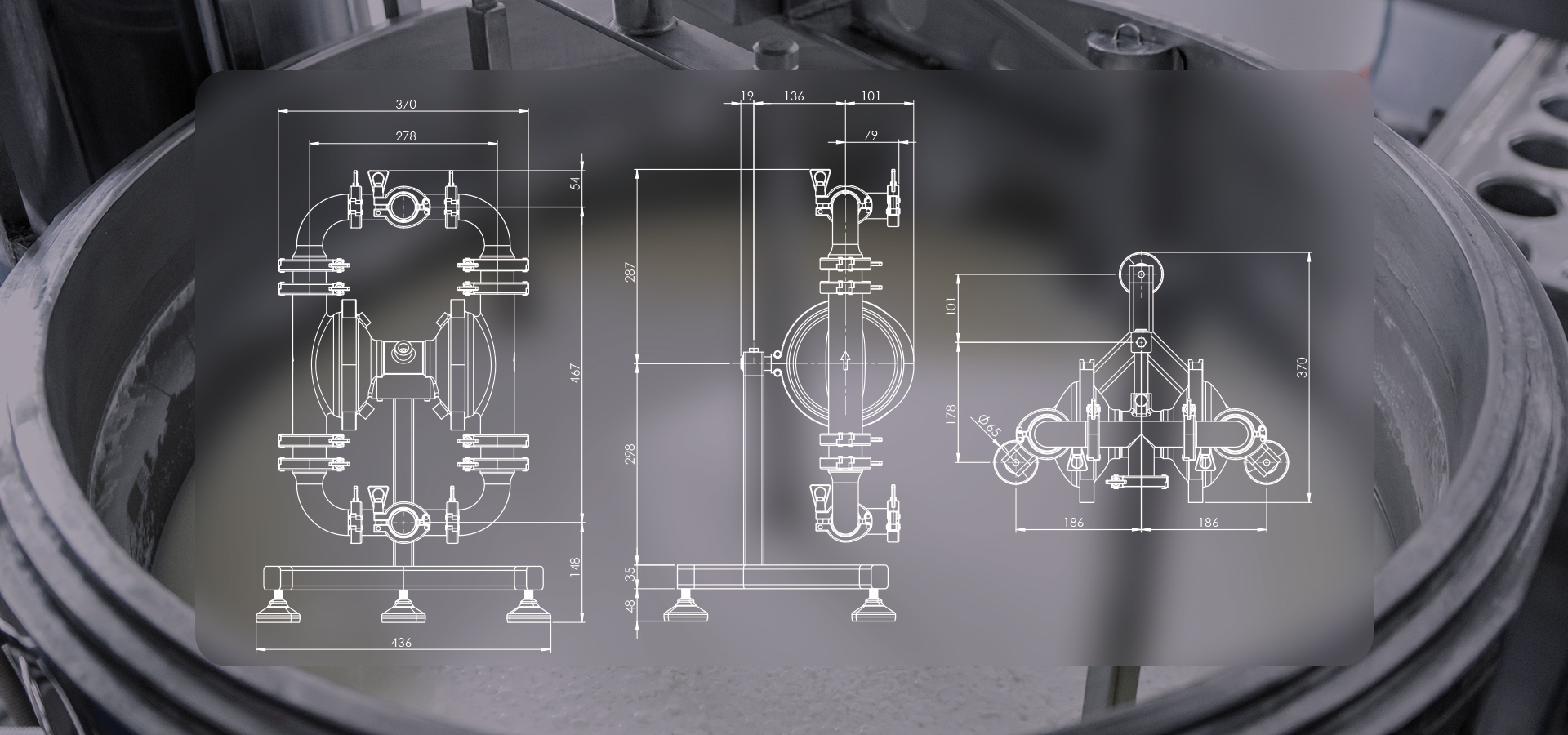

- MODELAISIBOXER 02

AISIBOXER-02 Dairy pump application

The AISIBOXER 02 pump plays a key role in optimizing two critical phases in the production of fresh cheeses:

- Cream transfer for burratine: the pump draws the cream from a dedicated container and gently channels it into the processing system, ensuring a constant and even flow. This continuity is essential for preserving the final product's quality, avoiding interruptions during the production process.

- Flexibility in managing raw materials: the dairy pump also allows the transfer of cream from alternative containers using a flexible suction hose. This versatility enables the company to optimize workflow, reduce machine downtime, and improve the overall efficiency of the production process.

Cleaning procedure

At the end of the cream transfer for burratine production, the pump undergoes a rigorous cleaning cycle to ensure the highest hygiene standards and prepare it for the next use.

- The transfer hoses are disconnected and replaced with those specifically dedicated to cleaning.

- The cleaning process involves hot water, steam, or detergents to ensure complete removal of any cream residue or impurities.

- Once the cleaning cycle is completed, the pump is rotated to remove any remaining liquid, ensure perfect drying and an impeccable preparation for the next production cycle.

Usage frequency of diary pump

The production of burratine and other fresh cheeses is planned to ensure a continuous and well-structured workflow. As a result, the AISIBOXER 02 pump is used five days a week, always ensuring efficiency and quality at every stage of the process.ng perfect drying and impeccable preparation for the next production cycle.

Why AISIBOXER-02?

The company specialized in producing fresh cheeses like burratine, mozzarella, and caciocavalli, initially had a cream transfer system that no longer met the growing production needs. During an important dairy sector fair, the company discovered the AISIBOXER 02 pump and immediately recognized its value due to its robust construction, high hygienic quality, and ease of cleaning. The AISIBOXER 02 pump was chosen to replace the outdated system, bringing significant improvements in operational efficiency and production process safety, especially in handling delicate raw materials like cream.

Results and customer satisfaction

After implementing the AISIBOXER 02 diary pump, the company experienced outstanding results. The pump not only met the high hygiene and food safety standards but also ensured continuous optimization of production. Thanks to its compliance with MOCA, the pump guarantees full adherence to current regulations, allowing the client to improve the quality and reliability of the production process. Additionally, the system’s reliability significantly reduced machine downtime, contributing to a smoother and more continuous production line, with clear improvements in overall productivity.