Optimization of the Production Process

AISIBOXER-01 / Pump for the Gluten-Free Pizza Industry

DiscoverCompany Profile

The client operates in the gluten-free and lactose-free frozen food sector, specializing in precooked meals formulated for celiac and lactose-intolerant consumers. As the third-largest Italian producer in this niche market, the company plays a pivotal role in addressing the increasing global demand for allergen-free foods, serving both domestic and international markets with strict adherence to food safety regulations and innovative product development.

- CLIENT Third-largest Italian producer

- INDUSTRYGluten-Free Frozen Food Industry

- SOLUTIONAISIBOXER 1

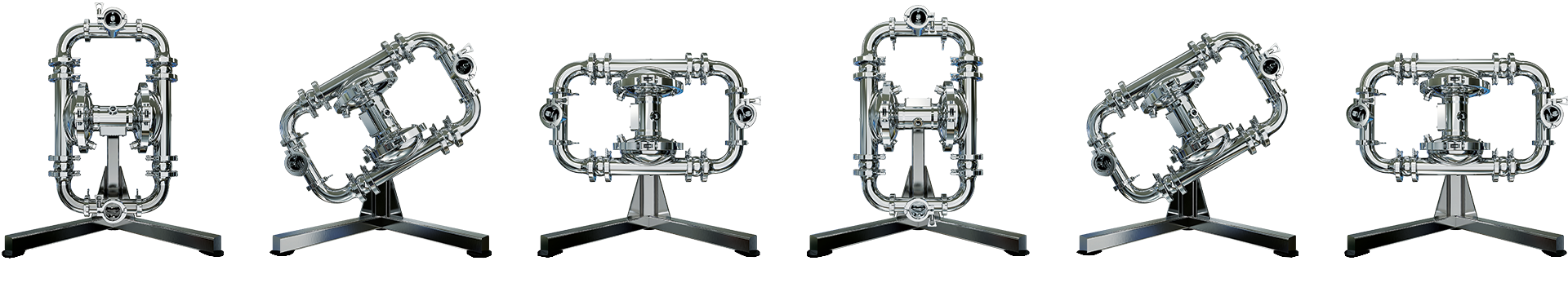

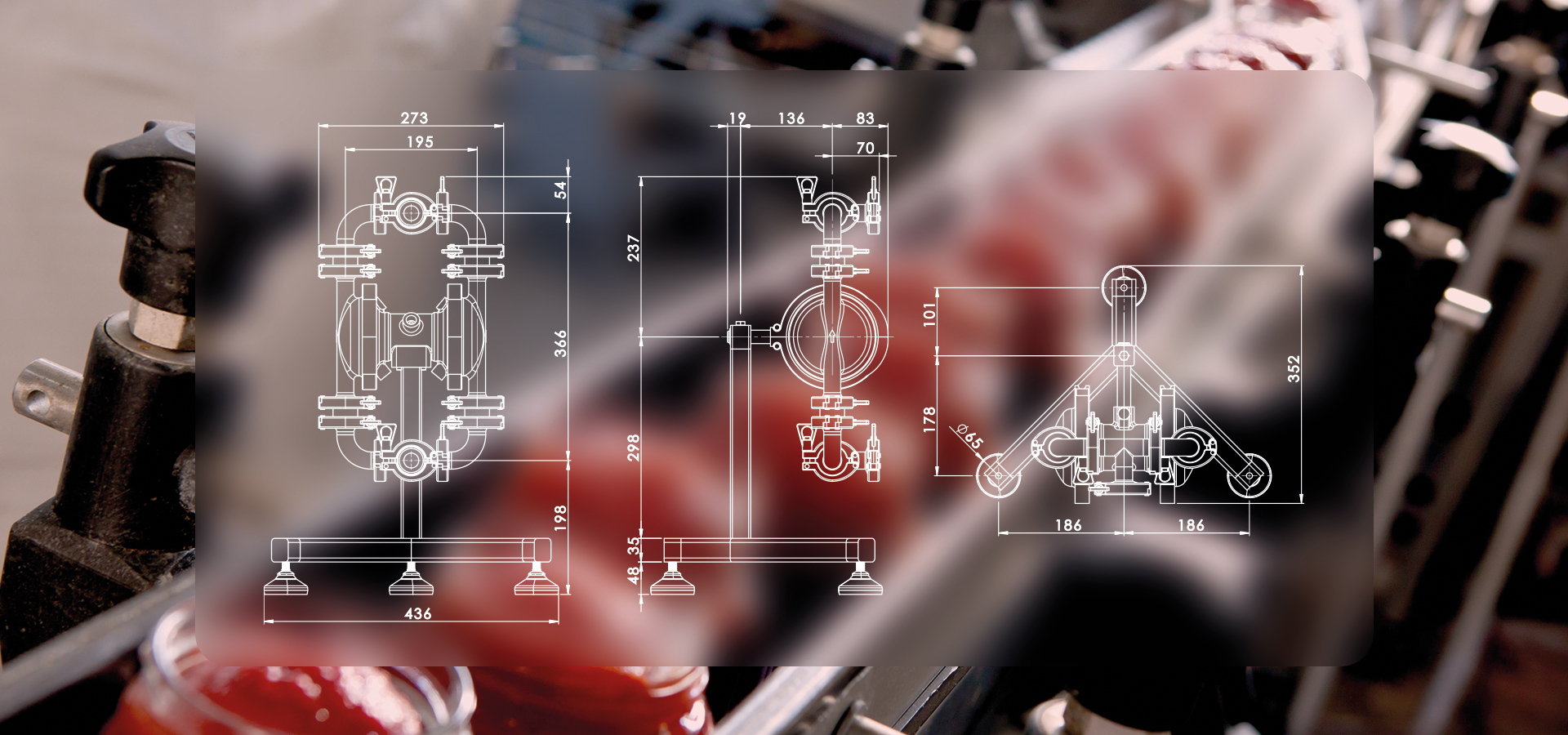

- MODELAB001AADWAAWCC--R0 with easel

AISIBOXER-01 Pump Application

The AISIBOXER-01 contributes to the optimization of two essential phases of the production process:

- Tomato Sauce Transfer. The pump draws the sauce from a stainless steel container and conveys it into a loading hopper, ensuring a steady and uniform flow. This continuity is essential for maintaining product quality and preventing production line interruptions.

- Flexible Product Handling. The pump also enables sauce transfer from alternative containers using a negative suction flexible hose. This versatility allows the customer to optimize workflow and reduce machine downtime.

Cleaning Procedure

At the end of the tomato sauce transfer process, the pump undergoes a thorough cleaning cycle to ensure maximum hygiene and prepare it for the next use.

- The transfer hoses are disconnected and replaced with dedicated cleaning hoses.

- The pump is washed with hot water, steam, or specific detergents to remove all residues.

- After washing, it is rotated to fully drain residual liquids, ensuring effective drying.

Usage Frequency

Production is structured to alternate between “white” pizzas (without sauce) and pizzas with tomato sauce. As a result, the AISIBOXER-01 pump is used 2–3 days a week, depending on production needs and batch management.

Why AISIBOXER-01?

Before adopting Debem’s solution, the company used an outdated transfer pump. During the CIBUSTEC trade fair, it discovered the AISIBOXER-01 and appreciated its superior construction, high hygiene standards, and ease of cleaning. Convinced by the pump’s performance, the company decided to upgrade its system, achieving a significant improvement in production efficiency.

Results and Customer Satisfaction

The customer expresses high satisfaction with the AISIBOXER-01’s performance, particularly its MOCA compliance, which ensures safety and adherence to food contact regulations. The pump’s hygienic design and reliability have helped optimize production, reduce downtime, and maintain high-quality standards at every stage of the process.