Food pumps: a practical guide to selection, integration and control

Food pumps are transfer devices designed to move fluids and emulsions while preserving the sensory properties and composition of the product. Food pumps are a strategic choice that affects quality, safety and process costs. This guide is designed to offer a practical reference: it outlines the truly decisive variables, explains what to check before purchasing and indicates how to set up control during operation. The aim is to help production, quality and maintenance managers select and integrate the solution that best suits their plant, with immediately applicable operational guidelines.

What are food pumps?

Food pumps are transfer devices designed to move fluids and emulsions while preserving the sensory properties and composition of the product. They feature suitable contact materials, low-roughness internal surfaces and sanitary connections to reduce stagnation and contamination. They ensure controlled flow with low mechanical stress and facilitate cleaning and inspection operations, benefiting the quality, safety and repeatability of the process.

When should hygienic pumps be preferred over standard solutions?

Hygienic food pumps are preferable to standard pumping solutions in the following conditions:

- Recipes with products sensitive to mechanical stress: sauces, creams, emulsions and shear-sensitive products that require delicate transfer.

- Frequent changeovers and significant washing times: when cleaning and sanitisation significantly affect line performance.

- Stringent traceability requirements: requested by customers and audits on contact materials, process parameters and records.

In these scenarios, hygienic pumps reduce residues, stabilise flow rates even under variable conditions and simplify inspections and maintenance.

What data is needed to select a pump for food?

The choice starts with the characterisation of the product: viscosity at working temperature, presence and size of suspended solids, sensitivity to air or oxidation. It continues with the performance required by the line (nominal and peak flow rate, height differences, expected losses) and hygiene requirements (compatible materials and seals, low roughness internal finish, quick connections and draining geometries). The picture is completed by the plant context: pipe layout, quality of available services, accessibility for inspections and interventions.

How to size and integrate hygienic in-line pumps?

Effective sizing starts with defining the actual flow rate required, checking the suction conditions (including overall pressure drops), and setting up a flow control consistent with the available services. In-line integration benefits from sanitary fittings and drainage paths to reduce stagnation, air-side adjustment when using AODDs for stable calibration, and standardised cleaning and inspection procedures to shorten changeovers and facilitate checks. To support your choice, below is a summary matrix linking the main inputs to the design effects.

| Selection inputs | What to fix | Effect on choice |

| Viscosity & T° | Operating range | Passage section and low stress principle |

| Solids | Size/fragility | Gentle geometries, adequate passages |

| Flow rate & losses | Nominal/peak + layout | Flow stability, NPSH/suction |

| Hygiene | Materials/finish/connections | Reduction of stagnation and cleaning times |

How to validate and document food pumps in operation?

Validation combines tests on 2–3 sample batches with recording of key parameters: flow rate/pressure, washing times and sequences, visual and metric checks on transfer stability. A routine periodic verification of set points, combined with scheduled inspections, maintains constant performance and provides a documentation ready for audits and customer requests.

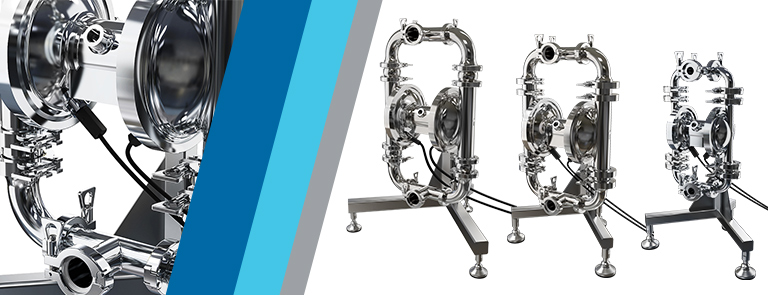

Discover the SANI DEBEM hygienic pump range

Evaluate configurations, contact materials and integration options for the SANI DEBEM range

A technical comparison allows you to align the recipe, line and objectives and define a coherent, validatable and sustainable proposal