Company Profile

An oil mill producing high-quality extra virgin olive oil required a reliable solution for transferring oil in the stages following pressing. The company operates with modern equipment and pays particular attention to hygiene, traceability and the preservation of product properties during all stages of processing.

- CUSTOMEROil mill and extra virgin olive oil producer

- SECTORFood industry – oil sector

- SOLUTIONHygienic pump for extra virgin olive oils

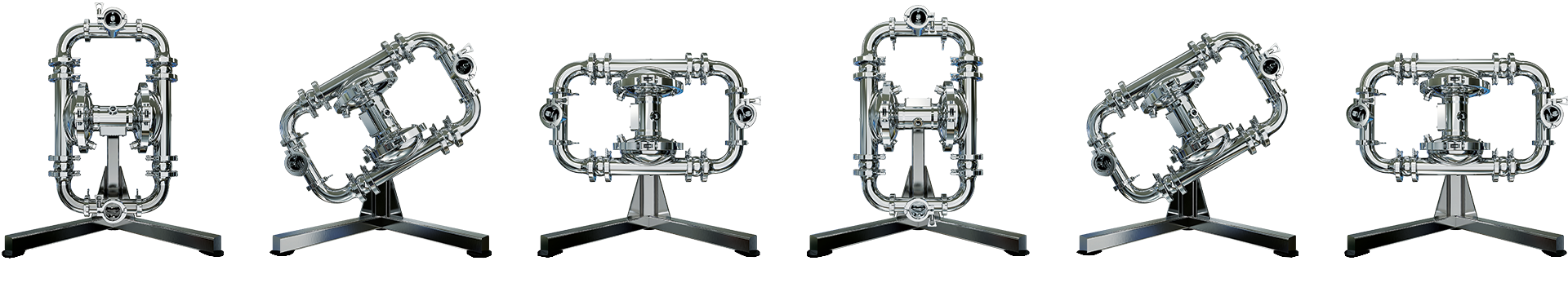

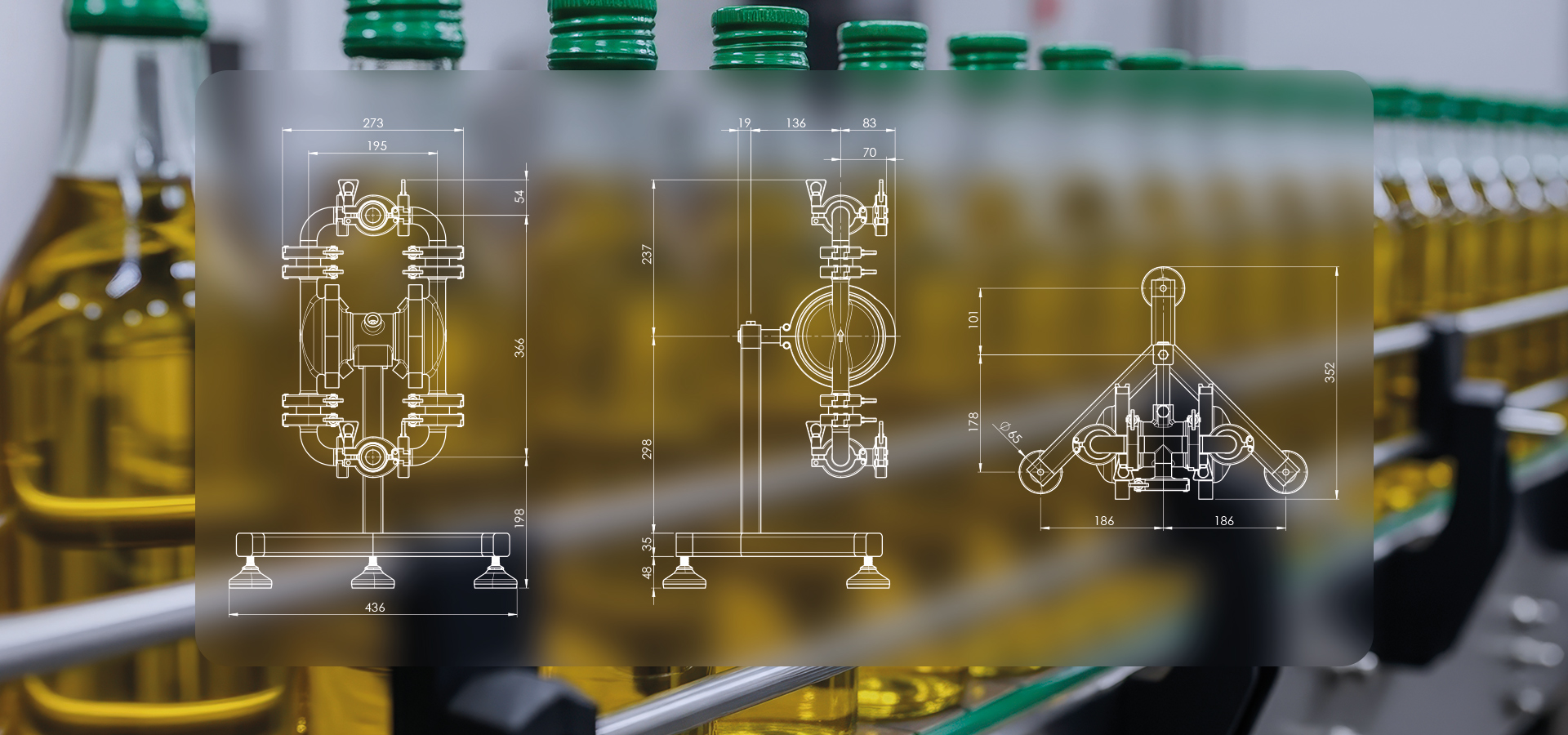

- MODELAISIBOXER 01

Application of the AISIBOXER-01 extra virgin olive oil transfer pump

The main requirement was to transfer extra virgin olive oil from decanters and intermediate tanks to storage and filtration systems in a controlled and continuous manner. The process had to take place without introducing air, avoiding mechanical stress and preserving the organoleptic qualities of the oil. After careful technical evaluation, the DEBEM AISIBOXER-01 pump was selected, which is particularly suitable for food applications that require delicacy, hygiene and operational reliability.

Cleaning procedure for oil transfer pumps

To ensure compliance with the hygiene standards of the oil industry and preserve the sensory properties of the oil, the washing procedure follows sequential steps that remove residues, oily films and micro-contaminations before restarting the cycle.

- Emptying and pre-washing: emptying the pump of oil, circulating hot drinking water. This step serves to remove most of the fatty residues before they stick to the internal surfaces. Continuous water flushing for a sufficient amount of time.

- Detergent washing: a detergent solution suitable for food use (typically alkaline, compatible with membranes and gaskets) is circulated at the recommended temperature. This removes oily films and micro-residues that water alone has not been able to eliminate.

- Rinsing and sterilisation: thorough rinsing with drinking water until all detergent has been removed, followed by a sanitisation cycle: hot water, steam or food-grade sterilising solution, according to the oil mill's HACCP procedure. At the end of the procedure, the AISIBOXER-01 pump allows total drainage thanks to its special rotatable structure.

Frequency of use and operational continuity of oil transfer pumps

The pump is used daily during the oil campaign, with intensive use during the olive harvesting and milling periods. Its robust construction allows continuous operation even over multiple shifts, ensuring reliability and reducing downtime during peak production phases.

Why choose the AISIBOXER-01 for transferring extra virgin olive oil?

The AISIBOXER-01 meets the requirements necessary to preserve the sensory quality of the oil, maintain certified hygienic conditions and reduce non-productive time. Specifically, the pump meets the following requirements.

- AISI 316L stainless steel body, compliant with FDA - MOCA standards, ideal for contact with extra virgin olive oil

- Gentle, low-shear transfer that preserves the organoleptic properties of the product

- Hygienic design compatible with CIP washing procedures

- Easy to disassemble and maintain, reducing intervention times

- Low running costs, thanks to the reduced number of components subject to wear

Oil transfer pump performance: results obtained

To highlight the operational impact, the results were measured in terms of process times, perceived quality and line stability, with positive findings across all key metrics.

- Improved efficiency in the transfer of extra virgin olive oil

- Preservation of the product's qualitative and sensory characteristics

- Greater continuity and stability of the production process

- Reduction in cleaning and maintenance times

- Better flow control and greater operational flexibility of the system