Optimisation of the production process

AISIBOXER-01 / Alcohol pump optimises the transfer of mixtures in premium gin

DISCOVERCompany profile

The company has been operating in the beverage & spirits sector for decades and is internationally recognised for the quality of its spirits. Production combines traditional processes (cold maceration, distillation in copper stills) with automated systems for controlling temperature, pressure and aromatic composition. Each batch of gin is created from a selection of botanicals (juniper berries, citrus fruits, spices, roots) infused in a high-alcohol hydroalcoholic base for varying lengths of time depending on the recipe. This phase requires particular care in handling to avoid the loss of volatile compounds and the degradation of the most delicate aromas. The company invests in low environmental impact and high energy efficiency technological solutions.

- CUSTOMERBeverage industry

- SECTORBeverage & Spirits – Production of gin and flavoured spirits

- SOLUTIONHygienic pump for alcoholic mixtures and botanical infusions

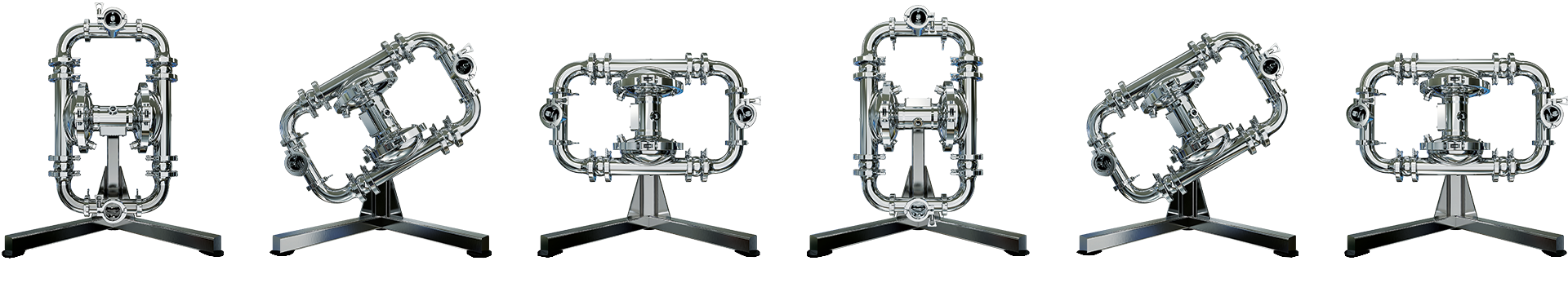

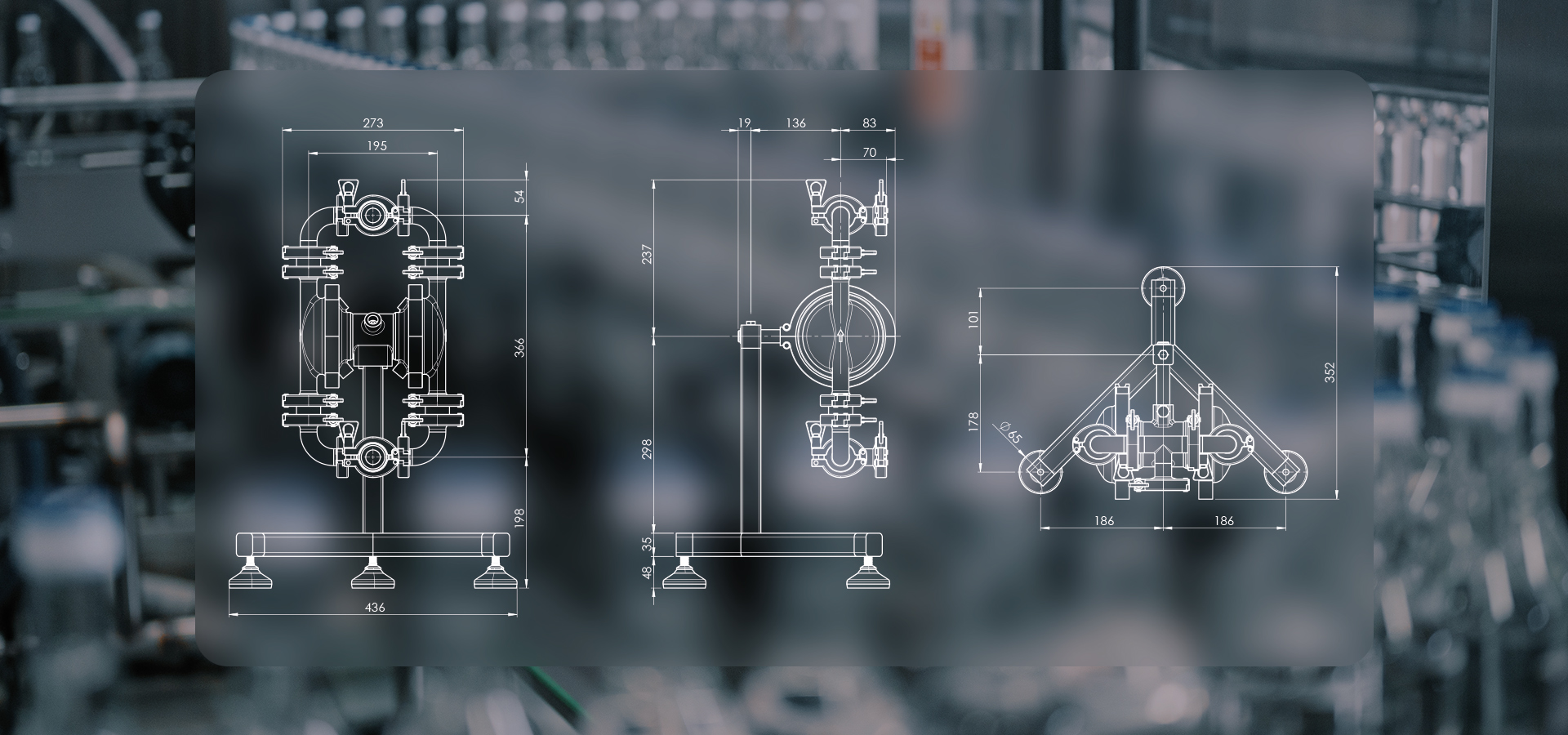

- MODELAISIBOXER 01

Application of the AISIBOXER-01 alcohol pump

Transfer of high-alcohol liquids between maceration tanks and distillation plants. Technical requirements:

- Preserving the aromas and essential oils of botanicals.

- Resist fluids with high alcohol content.

- Ensure rapid sanitisation between batches.

The AISIBOXER 01, thanks to its hygienic design and double diaphragm technology (AODD), proved to be the most suitable solution.

Rapid and traceable sanitisation process (CIP)

The alcohol mixture pump is integrated into a CIP system that complies with industry hygiene and sanitation standards:

- Rapid drainage via dedicated valves and pipe slope.

- Internal washing with food-grade detergents and demineralised water at a controlled temperature.

- Final sanitisation with steam (where required by technical specifications) or alcohol solution, followed by drying with sterile filtered air.

The complete cycle allows preparation for a new batch in less than 20 minutes, significantly reducing downtime.

Frequency and operation of the AISIBOXER-01 distillate pump

The AISIBOXER 01 distillate pump is used for up to 20 operating hours per day during periods of high production, alternating between transfer cycles and scheduled CIP washing. Its robust construction and resistance to alcoholic fluids guarantee consistent performance even with continuous operation 6-7 days a week.

Why use AISIBOXER-01 for the transfer of alcoholic mixtures?

- Food certifications (MOCA and FDA-compliant parts in contact with food).

- Constructed in polished AISI 316L, Ra <0,8 μm.

- Compatibility with alcoholic liquids and essential oils (with suitable sealing materials).

- Gentle handling with low mechanical stress.

- Reduced maintenance thanks to a limited number of parts subject to wear.

Results obtained from the AISIBOXER-01 alcoholic mixture pump?

- Increased transfer efficiency: reduction in transfer times between tanks by up to 20% (internal data).

- Aromatic stability: preservation of the most volatile aromatic notes thanks to low-impact handling.

- Reduced sanitisation times: -35% on CIP times compared to previous solutions.

- Improved process control: real-time monitoring of pressure, flow rate and temperature (via line system).

- Long-term reliability: consistent performance without extraordinary maintenance after months of intensive use.

- Optimisation of operating costs: less downtime and reduced energy consumption.